New plant already running

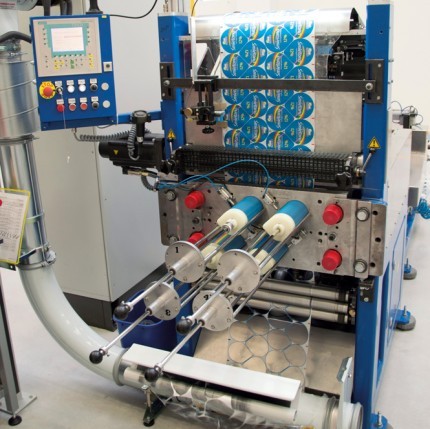

On January 7, 2014, after 9 months of construction works, we opened our new factory. It is one of the Europe’s most modern factories dedicated to manufacturing packaging for food, pharmaceutical and cosmetic industry. The production plant area is nearly 6000 sqm and it includes the Central and Eastern Europe’s only D class clean room (ISO 8), in which aluminum packagings for medicines are manufactured. The entire production process from printing, slitting, rewinding to packing takes place in sterile conditions. 26 HEPA filters, lock system and appropriate pressure levels in individual clean room areas guarantee the safest conditions for manufacturing pharmaceutical packaging. The factory is also equipped with flow cloakrooms which oblige all employees to take a shower before entering the production area. Appropriately designated zones regulate the flow of materials and employees. In the highest risk zone and in the high care zone wooden pallets are not used. Investments in new machines were not neglected in the new plant. New printing line and new, very efficient die-cutting machine were installed, as well as central pneumatic conveying system, new fully automated ink mixing station and a special room for solvent distillation. The new factory has manufacturing capacity of about 100 000 000 running meters but already at the stage of investment planning it was designed in such a way that it can be easily expanded. The new headquarters is a typical "greenfield" project. It is located just over 1 km from the built-up area, however, as it is situated only 3 km from the A2 Motorway exit , it takes only 20 minutes to get to the airport, 30 minutes to the Warsaw city center and only 4,5 hours to Berlin.